The making of Parmigiano Reggiano

The centuries old tradition that honors local production and gives life to your bowl of spaghetti

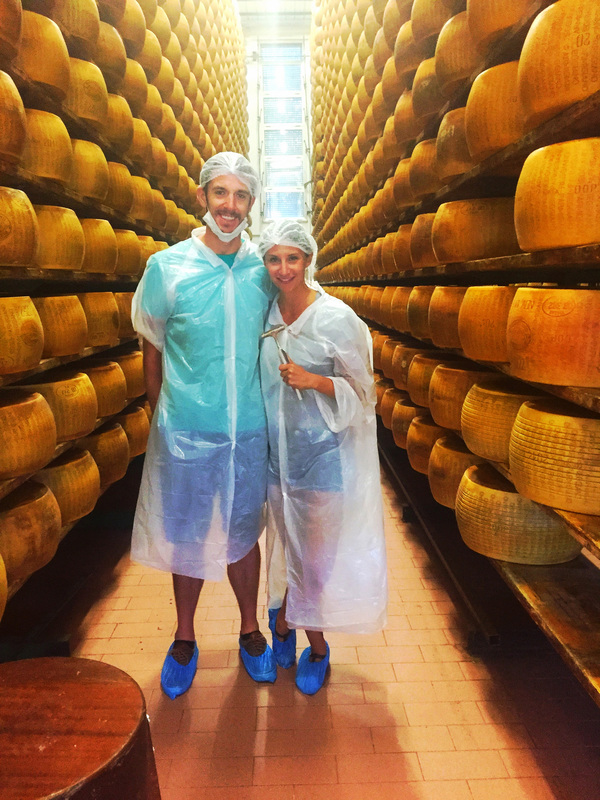

They’re stacked at least twenty rows high, towering overhead like skyscrapers, a vertical mass of one of the most delicious and heavily sought after cheeses in world; Parmigiano Reggiano.

Only once these hefty cylindrical wheels of cheese have gone through a precise, months long process will they get to this point of aging. The centuries old tradition dates back to 1200 AD and little has changed since that time. Much of this allure comes from the exactitude of its production, because only here, in this tiny region of Northern Italy, can Parmigiano Reggiano be made.

This factory, one of only 360 in the world producing Parmigiano Reggiano, makes 20 cheeses per day, each of which weigh about 80 pounds by the time they’re finished. Each factory has a cheese master and only one. The cheese is made every day and every day the cheese master oversees the production. The master at this factory is young, at least by cheesemaker standards (the previous cheesemaster held this post for 45 years). Still in his early forties, he recently moved to Parma from a smaller factory in the mountains. Still less than a year under his belt, no one has eaten his cheese yet, so he has a lot to prove. His fate is up to the consorzione and whether they think his cheese is any good. If it is, his contract to produce Parmigiano Reggiano with the 12 farmers in the local cooperative will be renewed. If it’s not up to standards, he’ll need to restart elsewhere.

Making Parmigiano Reggiano is a long and arduous process. It starts with raw, fresh milk from a small group of dairies that have contracts with the cheese makers. The cows are milked two times a day, with milk from the previous night partially skimmed while fermenting for 12 hours in natural conditions. In the early morning the cows are milked again. This time whole milk is delivered to the cheesemakers to be mixed with the partially skimmed milk from the night before. This is a process based on tradition, but the cheesemakers feel this specific balance is important. Once the milk is mixed together, whey is added as a “starter” and the mixture is heated to 37 degrees celsius, body temperature. Then comes the rennet, which works as a natural enzyme, and soon the milk will start to thicken, eventually turning into a soft wheel of cheese at the bottom of each copper vat.

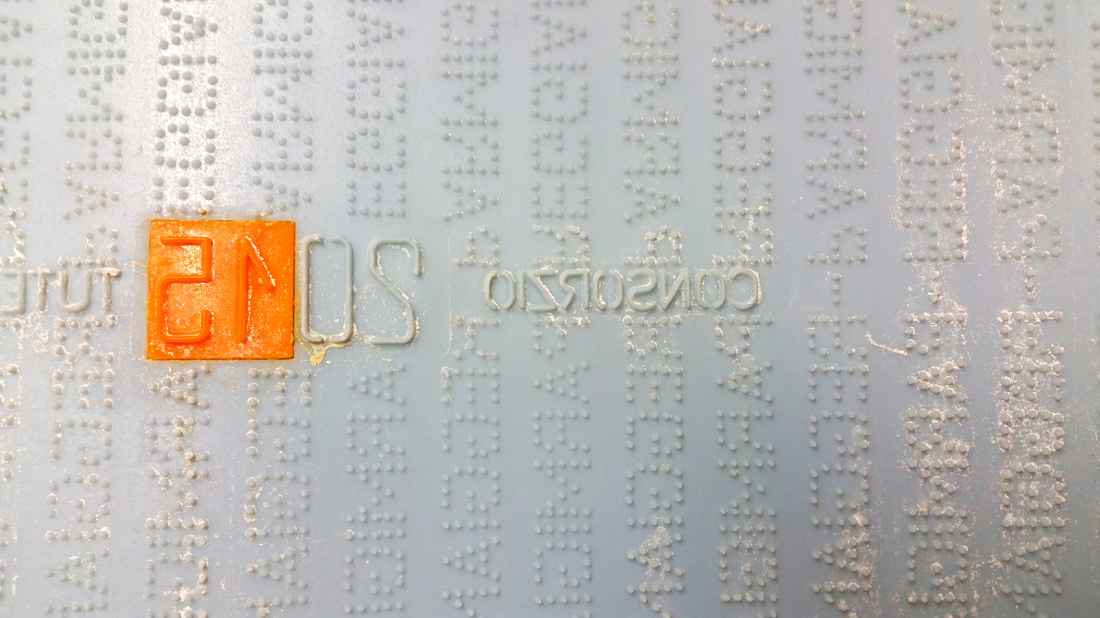

While it’s still soft, the sides of each wheel are wrapped with a casing that imprints the name “Parmigiano Reggiano”, as well as the information of the dairy in which it’s made. After two days in the “sleeping room,” the wheels are introduced to a salt bath (33% salinity) for one month, where they’ll slowly shrink, harden, and develop a thick rind. It will take at least 10 months for the salt to be evenly distributed throughout the wheel. Hence, the aging process. When it’s finished with the salt bath, the wheels are delivered to the aging room where they’ll stay for a year or more. This room, specifically, stores up to 17,000 cheeses.

While the production of Parmigiano Reggiano is highly local and in most ways quite sustainable, some parts of the heavily traditional process seemingly have room for improvement. The cows used to produce milk for Parmigiano Reggiano are treated well and fed a mix of all natural grain including alfalfa, wheat, oat, barley, and corn, however they are kept indoors at all times. Parmigiano Reggiano cheesemakers are also experimenting with vegetable rennet, which in recent years has received increased demand. Traditional rennet, used in many cheeses around the world, comes from the lining of a cows stomach, removed after slaughter, meaning most cheese isn’t actually vegetarian. And while the amount used is minimal (about 1 gram per wheel of Parmigiano Reggiano), a switch to vegetable rennet and better treatment of the cows in this process would make Parmigiano Reggiano more sustainable.

On the flipside, what is completely sustainable about Parmigiano Reggiano is almost every other single piece of this tedious process. Because the cheese is designated as Parmigiano Reggiano based on the DOP (denominazione origine produzione), almost everything that goes into it is both local and carefully watched. The milk comes from one of 12 farms in the coop that works with this cheesemaker and the farmers must grow at least 70% of the feed for their cows themselves, meaning almost everything about Parmigiano is locally-sourced, from this beautiful and prosperous region. It’s the quality standard that drives these naturally sustainable practices, since each cheese must be tested and approved by expert members of the consorzione (consortium) in order to receive the sacred branding of Parmigiano Reggiano.

Like the beautiful wines made by Salcheto in Montepulciano, or traditional Balsamic Vinegar made by San Donnilo in Modena, Parmigiano Reggiano is a tribute to high quality ingredients and careful manufacture. The appreciation of the land, along with a patience for time-consuming processes makes these products exponentially better than any alternative. And when we use appreciation, care, and patience in making what we eat and drink, it’s naturally better and more sustainable.